- Home +

- Product +

- About us +

- Video +

- Ritop park +

- Ritop Join +

- Oem/Odm +

- News +

1、Product composition:

This product is made of epoxy siloxane as the main body, multi-copolymer copolymer and the corresponding environmental protection solvent after multiple polymerization and grafting modification reaction prepared by the three anti coating.

2、Product use:

Widely used in radar, microwave radio, carrier oscilloscope transformer, printed circuit board, electronic components, cultural relics, stone carving, calligraphy and painting and other important items protection and machine protection. The product complies with IPC-CC-830, International paint safety standards and EU RoHS testing standards and is UL-94V0 certified.

3、Product performance:

3.1 Has the characteristics of high solid content, low acid value, chemical solvent resistance;

3.2 Good anti-mold performance;

3.3 High insulation resistance, high breakdown voltage, arc resistance, electric spark resistance, low dielectric loss, good insulation performance;

3.4 Good temperature change resistance, cold and heat shock resistance;

3.5 Good moisture resistance, insulation and chemical resistance;

3.6 Unique anti-counterfeiting and fluorescent tracer formula.

4、Technical index:

4.1 Reference Standards

The following standards contain provisions which, by reference in this standard, constitute provisions of this standard. This standard shall not be applicable to any dated reference; All undated reference standards, the new version of the standard as the reference standard.

GB 1981-89 Test method for solvent insulating paints

GB/T 15022-94 Definitions and general requirements for solvent-free polymerizable resin composites for electrical insulation

GB/T 15023-94 Test method for solvent-free polymerizable resin composites for electrical insulation

4.2 Product Requirements

All products shall meet the requirements specified in the following table. If the customer has additional requirements beyond the following table, special instructions shall be given in the order contract.

SPECIFICATION ITEM item | SPECS Gauge lattice | STANDARD Reference standard |

appearance | Slightly turbid transparent liquid, no mechanical impurities | GB1721 |

Viscosity (25±2℃) Coated -4# cup (s) | 12±2 | GB/T6753.4 |

Solid content(%) | 26±2 | GB1725 |

Acid number(mgKOH/g) | ≤10 | GB 1981.2-2009 |

Adhesion (drawing method) level | 0 | GB/T9286 |

pliability | pass | GB/T 1981.2-2009 |

Drying time Surface drying(23±2℃,65±5%RH) Completely dry(23±2℃,65±5%RH) |

≤25min ≤24h |

GB1728 |

Heat resistance | 21Periodic pass | JB/T839-88 |

Salt spray prevention | 24Hourly pass | JB1606 |

Mold proof | 28 days (Level 0-2) Pass | GB/T1741-2007 |

Acid resistance (5% hydrochloric acid solution immersion) | 24h pass | / |

Alkaline resistance (5% sodium hydroxide solution immersion) | 24h pass | / |

Hot and cold cycle shock (-40±2℃-130±2℃,100次) | pass | IPC-TM-650, 2.6.7.1 |

Moisture resistance (Constant temperature40±5℃Constant humidity95±5%RH,96h) Moisture resistance (Constant temperature 85±5℃ constant humidity 85±5%RH,168h) |

pass | IPC-TM-650, Test Method 2.6.3.4 |

Breakdown strength (normal)(KV/mm) | ≥20 | JB-906 |

PV(Ω·cm) 常态 (23±2℃,65±5%RH) | ≥1×1013 | GB/T1410 |

Note: The turbidity of this product is caused by the addition of defoamer, not due to water or deterioration, and will not affect the quality!

The above data are the test results after coating the comb electrode plate with a dry film thickness of 40um and curing for 168h. If the customer needs to do any type test, it must ensure that the dry film thickness is not less than 40um and the paint film is completely cured before testing. Curing conditions are normal temperature (25℃, 55%RH) 168h or 60℃*24h.

5. Construction methods:

5.1 Before coating, the coated parts need to be purified, and there should be no dust, particles and other impurities;

5.2 According to the structure and technical requirements of the pre-coated parts, choose spraying, dipping and brushing construction methods, and according to

The coating process requires reasonable use of diluent to adjust the viscosity of the coating.

5.3 After application, surface drying can be less than 25min at room temperature, and practical drying can be less than 24 hours (25±2℃,65±5%RH).

If the spray machine with hot air circulation heating system is sprayed and baked (60±2℃,65±5%RH), the paint film is dry

Less than 5min;

5.4 Due to the fast drying characteristics of the protective agent, such as dip coating or brush coating process, the paint liquid in the paint tank must be small

Add, and add when you're done. If the viscosity increases, special thinner and fresh paint solution can be used to adjust to the standard viscosity

Degree. If it is not expected to be used within 2 hours, pour the paint into the bucket and seal the lid.

5.5 If manual coating construction is used, when the relative humidity is greater than 85%RH, the coating construction should be suspended to prevent

Undesirable changes in paint solution and film. The spraying machine with hot air circulating heating system is used for spraying and baking

Workers are not affected by the environment.

6、Construction condition:

Condition of the piece | Clean and dry, insulation resistance and electrical strength meet the design requirements | |

Paint preparation | According to the requirements of customers on the thickness of the film can be used directly, can also be used with diluent | |

Dip coating | normotherm | ≥1min (preferably not bubbling) |

Brush coating | normotherm | Brush evenly on the workpiece |

solidification | Normal temperature surface dry less than 25min | Fully cured in 24 hours |

Various performance tests | If it is necessary to do any type of experiment, it is necessary to continue to cure at room temperature for 168 hours after the surface of the experimental sample is dry, in order to obtain the best test results, and it can also be baked at 60℃ for 24 hours after cooling. | |

7、Matters needing attention:

7.1 The storage environment must be a dry and ventilated room with the temperature ranging from 5 ° C to 35 ° C and relative humidity ranging from 50 to 80%RH

Direct light, the paint should be sealed and stored in a cool, dry place, away from fire and light storage, keep good ventilation.

7.2 The paint is irritating to the skin, avoid direct contact with the skin and eyes, if contact with the skin, please use

Wash with soapy water. In case of contact with eyes, seek medical attention immediately.

7.3 Before use or after thinning, please stir well before use.

7.4 The product storage period is 6 months. Beyond the storage period, when the indicators are qualified, it can still be used.

8、Packaging, storage, transportation:

Iron drum sealed packaging, this product should be stored in a cool and ventilated dry place, isolated from fire, away from heat sources. The storage period is 6 months, beyond the storage period, it is necessary to re-test according to the standard provisions, if the result meets the requirements, it can still be used, the product should be transported to prevent rain, sunlight exposure, and comply with the relevant provisions of the transportation department on the transportation of hazardous chemicals.

9、Safety and environmental regulations:

This product contains flammable organic solvent, should be used in accordance with the painting operation safety regulations and technical operation specifications, the construction site should be far away from fire, ventilation, fire prevention, anti-static, anti-poisoning and other protective measures.

10、Packing specification:

15KG/ barrel

24KG/ box (4KG/ can 6 cans/box)

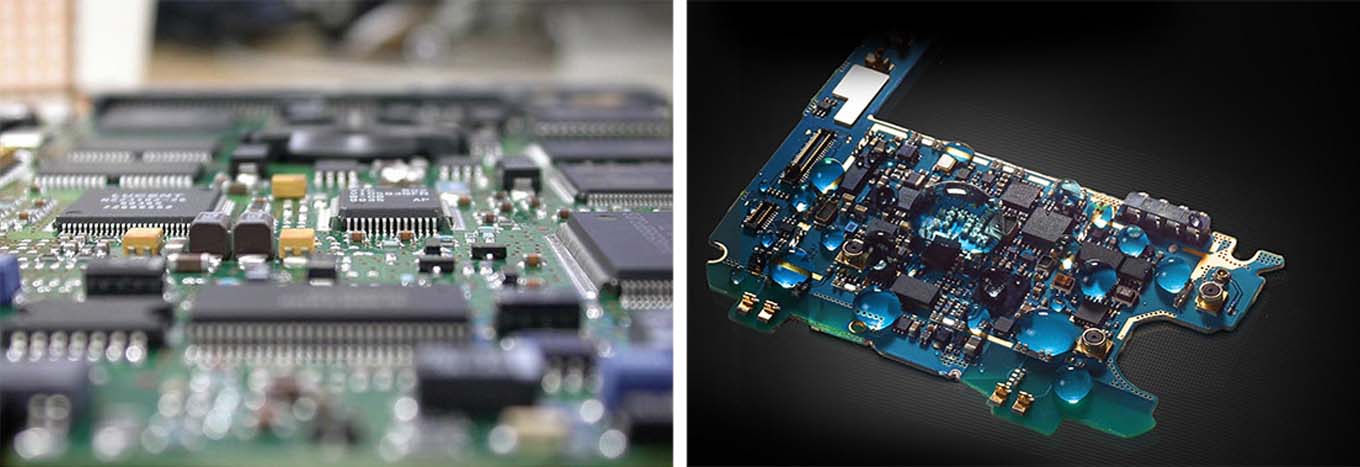

Application field of conformal coating

conformal coating can provide protection for electronic circuits in household appliances, making them resistant to harmful substances such as water, moisture, insects, etc. in offices and homes. It can be applied to soybean milk machine, coffee machine, Induction cooking, dryer, dishwasher, air conditioner, computer, bathroom electronics, electric car, etc.

The automotive industry requires conformal coating to protect circuits from the hazards of several situations, such as gasoline evaporation, salt spray, brake fluid, etc. The application of electronic systems in automobiles is constantly growing rapidly, so the use of conformal coating has become a basic requirement to ensure the long-term reliability of automotive electronic devices. For example: computer control systems, air conditioning, automotive electronics.

Due to the unique nature of the usage environment, aviation, aerospace, and navigation environments have strict requirements for electronic equipment, especially under fast pressurization and decompression conditions, good circuit performance must still be maintained. The pressure resistance stability of anti paint is therefore widely used. For example, satellite systems, military control systems, flight route control systems, navigation systems, and radar control systems.

conformal coating can protect electronic equipment from water, moisture, external chemicals, and special environmental erosion, ensuring its continuous stability. Its application range is very broad. For example, LED display screens, LED guardrail tubes, solar energy, instruments, power supplies, frequency converters, consumer electronics, anti-theft and fire alarm devices, etc.

Product parameters

Reminder: Support enterprise sample or personalized product customization for conformal coating users: flame retardant, temperature resistant, pressure resistant, thick coated, boiled, quick drying, fluorescent, and odor; The conformal coating meets the coating process of 20um~60um thickness. For customized requirements above 60um, you can directly contact our relevant personnel. Our company has passed the ISO: 9001 international quality management system certification, ISO: 14001 environmental management certification system, and TS: 16949 certification system. The following products comply with Chinese national standards and comply with European, American, and Japanese product standards such as IPC/JIS/UL/ROHS/REACH.

RTLV9669-1 Technical Data Sheet

Product name: Three anti-paint

Product Number: RTLV9669-1

Product brand:RITOP

Packing specification: 15KG/24KG (4KG/ can 6 cans/box)

Sales unit: barrel/box

Product description:

1. Product composition:

This product is made of epoxy siloxane as the main body, multi-copolymer copolymer and the corresponding environmental protection solvent after multiple polymerization and grafting modification reaction prepared by the three anti coating.

2、Product use:

Widely used in radar, microwave radio, carrier oscilloscope transformer, printed circuit board, electronic components, cultural relics, stone carving, calligraphy and painting and other important items protection and machine protection. The product complies with IPC-CC-830, International paint safety standards and EU RoHS testing standards and is UL-94V0 certified.

3、product performance:

3.1 Has the characteristics of high solid content, low acid value, chemical solvent resistance;

3.2 Good anti-mold performance;

3.3 High insulation resistance, high breakdown voltage, arc resistance, electric spark resistance, low dielectric loss, good insulation performance;

3.4 Good temperature change resistance, cold and heat shock resistance;

3.5 Good moisture resistance, insulation and chemical resistance;

3.6 Unique anti-counterfeiting and fluorescent tracer formula.

4、Technical index:

4.1 Reference Standards

The following standards contain provisions which, by reference in this standard, constitute provisions of this standard. This standard shall not be applicable to any dated reference; All undated reference standards, the new version of the standard as the reference standard.

GB 1981-89 Test method for solvent insulating paints

GB/T 15022-94 Definition and general requirements for solvent-free polymerizable resin composites for electrical insulation

GB/T 15023-94 Test method for solvent-free polymerizable resin composites for electrical insulation

4.2 Product Requirements

All products shall meet the requirements specified in the following table. If the customer has additional requirements beyond the following table, special instructions shall be given in the order contract.

Note: The turbidity of this product is caused by the addition of defoamer, not due to water or deterioration, and will not affect the quality!

The above data are the test results after coating the comb electrode plate with a dry film thickness of 40um and curing for 168h. If the customer needs to do any type test, it must ensure that the dry film thickness is not less than 40um and the paint film is completely cured before testing. Curing conditions are normal temperature (25℃, 55%RH) 168h or 60℃*24h.

5、Construction method:

5.1 Before coating, the coated parts need to be purified, and there should be no dust, particles and other impurities;

5.2 According to the structure and technical requirements of the pre-coated parts, choose spraying, dipping and brushing construction methods, and according to

The coating process requires reasonable use of diluent to adjust the viscosity of the coating.

5.3 After application, surface drying can be less than 25min at room temperature, and practical drying can be less than 24 hours (25±2℃,65±5%RH).

If the spray machine with hot air circulation heating system is sprayed and baked (60±2℃,65±5%RH), the paint film is dry

Less than 5min;

5.4 Due to the fast drying characteristics of the protective agent, such as dip coating or brush coating process, the paint liquid in the paint tank must be small

Add, and add when you're done. If the viscosity increases, special thinner and fresh paint solution can be used to adjust to the standard viscosity

Degree. If it is not expected to be used within 2 hours, pour the paint into the bucket and seal the lid.

5.5 If manual coating construction is used, when the relative humidity is greater than 85%RH, the coating construction should be suspended to prevent

Undesirable changes in paint solution and film. The spraying machine with hot air circulating heating system is used for spraying and baking

Workers are not affected by the environment.

6、Matters needing attention:

6.1 The storage environment must be a dry and ventilated room with the temperature ranging from 5 ° C to 35 ° C and relative humidity ranging from 50 to 80%RH

Direct light, the paint should be sealed and stored in a cool, dry place, away from fire and light storage, keep good ventilation.

6.2 The paint is irritating to the skin, avoid direct contact with the skin and eyes, if contact with the skin, please use

Wash with soapy water. In case of contact with eyes, seek medical attention immediately.

6.3 Before use or after thinning, please stir well before use.

6.4 The product storage period is 6 months. Beyond the storage period, when the indicators are qualified, it can still be used

7、Packaging, storage, transportation:

Iron drum sealed packaging, this product should be stored in a cool and ventilated dry place, isolated from fire, away from heat sources. The storage period is 6 months, beyond the storage period, it is necessary to re-test according to the standard provisions, if the result meets the requirements, it can still be used, the product should be transported to prevent rain, sunlight exposure, and comply with the relevant provisions of the transportation department on the transportation of hazardous chemicals.

8、Safety and environmental regulations:

This product contains flammable organic solvent, should be used in accordance with the painting operation safety regulations and technical operation specifications, the construction site should be far away from fire, ventilation, fire prevention, anti-static, anti-poisoning and other protective measures。

9、Packing specification:

15KG/ barrel

24KG/ box (4KG/ can 6 cans/box)

The detailed technical parameters of each product of the conformal coating can be found in its individual product introduction, and there will be no further expansion here

Sharp coating advantages

Support on-site inspections and spot checks of products

•Welcome customers to come to the factory for on-site inspection;

•Support online access to qualification documents such as ISO9001, ISO14001, IPC, JIS, UL, ROHS, REACH, etc;

Localization and nationalization dual mode transportation

•Before transportation, the product needs to undergo five testing processes: packaging pressure, temperature, humidity, sealing and squeezing, and overturning to ensure that the product is not affected by the environment during transportation;

Support on-site inspections and spot checks of products

•Welcome customers to come to the factory for on-site inspection;

•Support online access to qualification documents such as ISO9001, ISO14001, IPC, JIS, UL, ROHS, REACH, etc;

15 day package return and exchange

•If there are quality issues with the product, unconditional original return or exchange within 15 days;

•Provide customers with online consultation, remote guidance, and other services within one year;

Ritop strength

CONTACT US

If you interested any products, please contact with us.